Our client was facing challenges in optimizing the design of their wiper blades. Our client was working with a supplier who was taking 8 – 10 hours to refine each design iteration by measuring the radius of curvature for the wiper angle interval to analyze the curvature. To add to the difficulty, the client was receiving non-parametric models from the supplier, which does not allow any editing for further development by the client themselves. This implied that the client always had to send modification requests back to the supplier who spent more time working on each iteration manually. This tedious process and multiple iterations led to the client approaching Goken to investigate an automated process that can help optimize the design on wiper blades.

Goken’s first step was to approach this challenge by developing an algorithm that identifies free variables while imposing constraints and range of movement. Goken then used this algorithm to build the optimization tool that was able to analyze the wiper blade design against the curvature of the windshield surface.

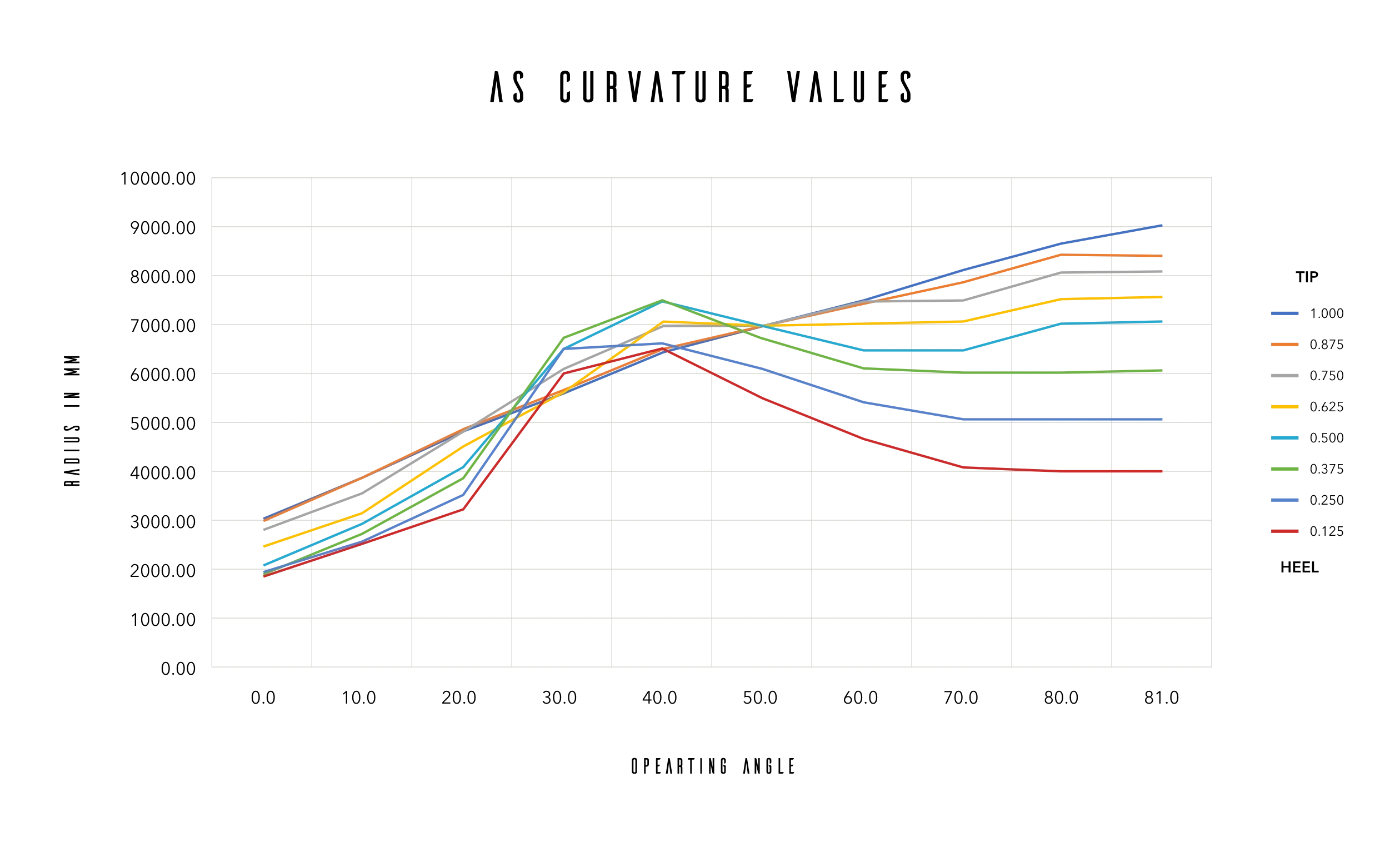

Since the wiper blade is a moving part against the windshield surface, the performance was analyzed by measuring the radius of curvature for every interval of wiper rotation along the length of the wiper blade. Any anomaly in its performance can be evaluated by measuring the deviation at the tip and heel of the wiper blade.

Goken used knowledge-based engineering tools such as EKL (Enterprise Knowledge Language) to measure the radius of curvature, which was then exported to excel to automatically create a chart with curvature deviation for visual analysis. We built a macro that computed multiple iterations until the final design specifications were met. With this approach, the analysis was performed in a couple of minutes and saved the client hours of analysis and optimization time.