Here is a challenge that is unique to start-ups and more specifically, EV (Electrical Vehicle) start-ups - Developing a product while also building the infrastructure that supports the development of this product. This includes PLM infrastructure with all its modules of requirements, configuration and change management, establishing processes around design and development, procurement, supplier integration. As this infrastructure evolves, there is a need to upskill existing associates and ensure that new associates onboarded are acclimatized to these processes and can effectively integrate into the organization’s way of product design and development.

Goken worked with a EV start-up to address this very challenge. The EV was impacted by the ongoing development of a framework for product development combined with an aggressive development schedule. To add to this, design engineers and supporting personnel have varied backgrounds and skill levels in using 3DExperience CATIA and are now tasked with working in a new PLM environment with limited understanding of work processes for milestone events and associated requirements.

Our goal was to streamline understanding, work with the PLM and Engineering group to standardize design, release, revision, and configuration management processes using 3DExperience, help Engineers and supporting personnel understand product structure and associated processes.

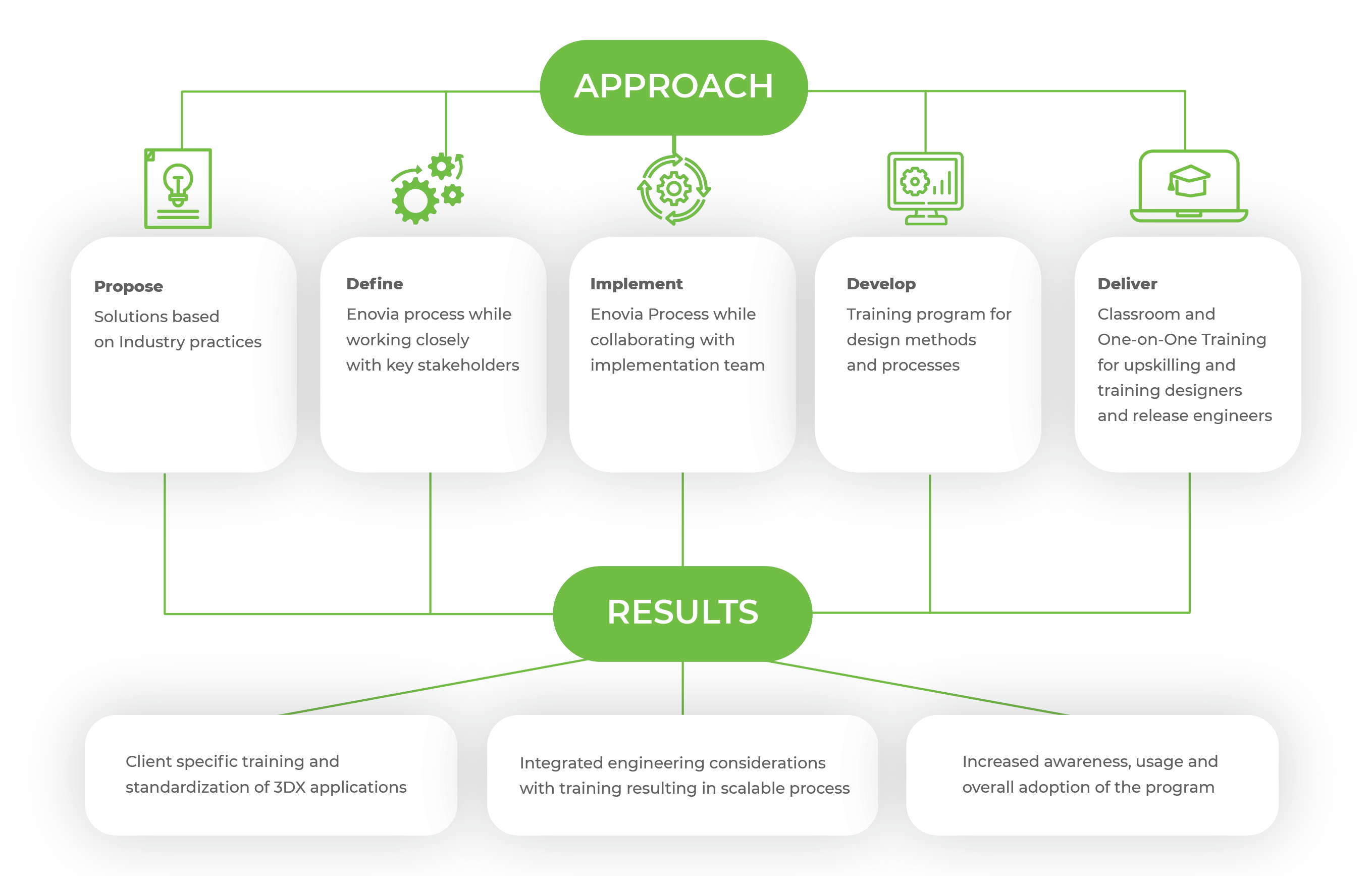

Goken’s team of highly skilled engineers worked with the stakeholders and the 3DExperience (3DX) implementation team to document existing and desired process flows. Goken then proposed workflows for new process. Upon implementation, Goken offered training to the Designers and Release Engineers on the various Enovia processes, which include Change Management process, Variation management, Drawing and Data Issue management, BOM and Revision management.

This project resulted in increased awareness and therefore standardized usage of PLM processes and associated applications with the 3DExperience suite of products. Organizational specific training in 3DExperience Enovia helped with standardizing application across the organization. Integrating engineering considerations with process flow and training ensured that work methods are effectively conveyed.

Overall, the client was able to realize increased output and efficiency by streamlining working styles and application through better management future challenges, reduced cost impacts from design errors and rework.