How Goken leveraged its Tech Center to manage peak loads for new supplier onboarding

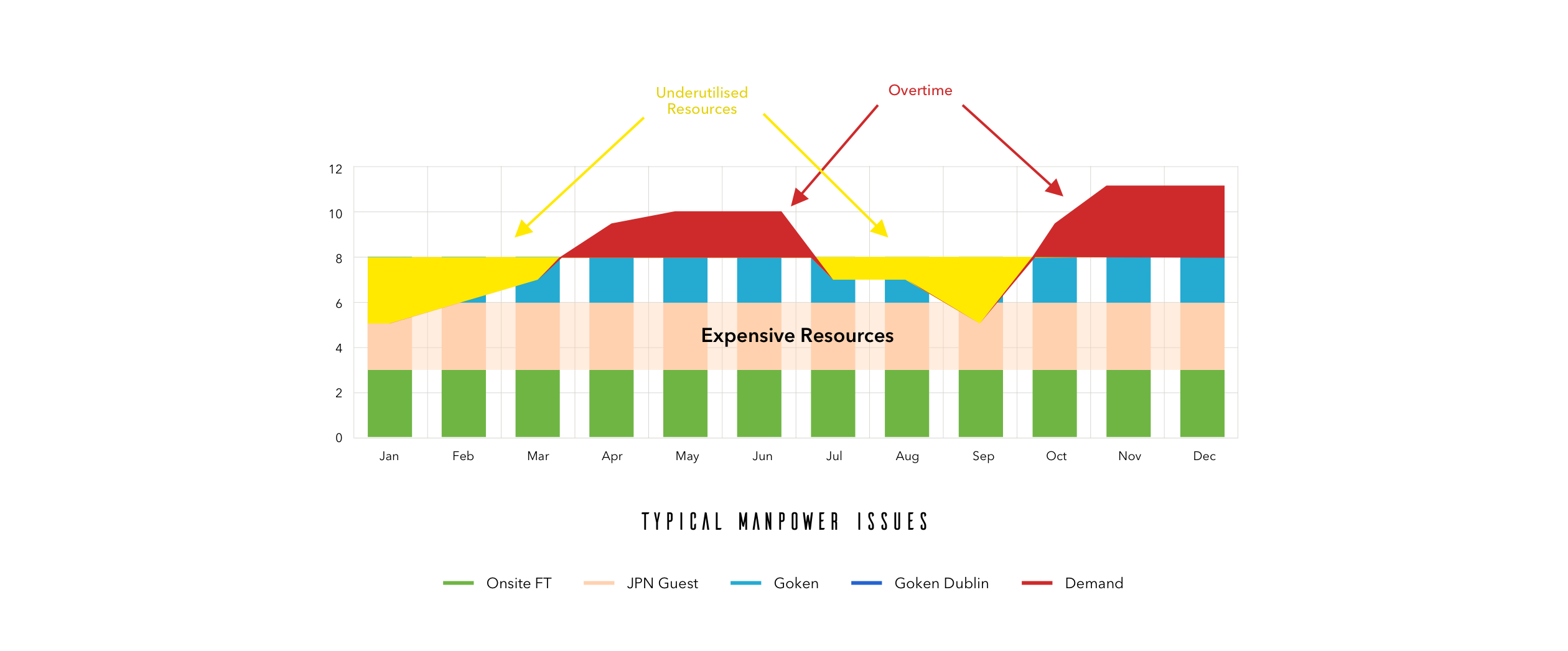

Companies often face challenges with ramping up hiring during peak development times. Typically, they are not geared to quickly hire, train, and deploy resources for a project within a short span of time. Moreover, there is also the risk of under-utilized resources when workload goes down in the next few months. Goken often supports companies that face such challenges.

One of our clients had insufficient resources during peak times, leading to high overtime for their existing associates. Deadlines were missed and the staff was overworked, which led to quality issues. Their team of 6 engineers were working at the Original Equipment Manufacturer (OEM) site. Having engineers visit Japan to US to support the project had also proved to be extremely expensive.

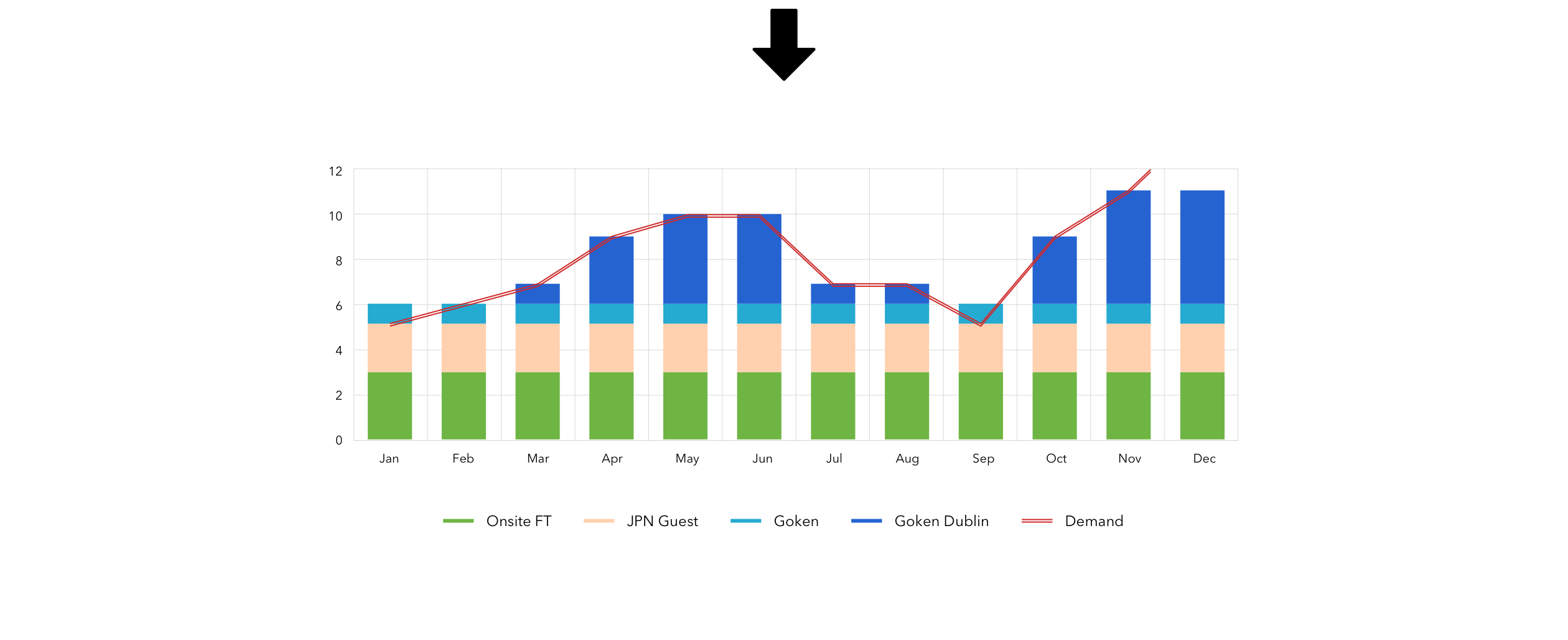

To address this issue, Goken proposed resource changes while not compromising the quality of work. We added two part time resources from the Goken Technology Center (GTC) to the client’s team. These two resources would support based on workload requirements. We also added an engineer to serve as full-time onsite liaison support. This combination worked well, and the team was able to deliver on time.

During the course of the 12-month development project, there were certain peaks and valleys of workload. During peak periods, Goken was able to utilize the resources from GTC to support and when the workload dropped off, the part-time resources were allocated to different projects thereby ensuring the client received the support they needed when they needed it. Goken’s ability to deploy resources in a short duration helped to balance the workload for the client resources thereby reducing the overall risk of burnout and the associated quality issues.

The benefits of the supplier were multi-fold. The supplier delivered the data and drawings for each development phase on-time. The supplier saved approximately 100,000 USD in a year (9.5% of the development cost) while eliminating underutilized resources during valleys, minimizing overtime during peaks, and reducing dependency on Japanese engineering resources.